Ultrasonic Air Leak Detector UL-102

Ultrasonic Air Leak Detector UL-102 Specification

- Specimen Size

- Various (Handheld/no limitation)

- Humidity

- â¤80% RH

- Operating Temperature

- 0°C ~ 40°C

- Display

- LED Bar Indicator + Audio output

- Response Time

- Instantaneous

- Test Material

- Metal, Plastic, Rubber, etc.

- Gas Pressure

- Any pressurized gas systems

- Number of Specimens

- Single point or multiple

- Test Range

- 36 kHz ± 2 kHz

- Temperature

- 0°C ~ 40°C

- Power Supply

- 9V Alkaline Battery

- Accuracy

- High sensitivity for location of micro-leaks

- Sensor

- Ultrasonic Receiver/Transmitter

- Type

- Ultrasonic Air Leak Detector

- Use

- Detection of air/gas leaks in pipes, valves, tanks, fittings

- Test Medium

- Air/Compressed Gas

- Operating Voltage

- DC 9V Battery

- Shell Material

- ABS Plastic

- Net Weight

- About 300g

- Pedestal Size

- Compact, Handheld

- Port Size

- Standard

- Operating Mode

- Continuous

- Environment

- Indoor and Outdoor

- CE Certified

- Yes

- Headphone Jack

- Yes, for audio indication

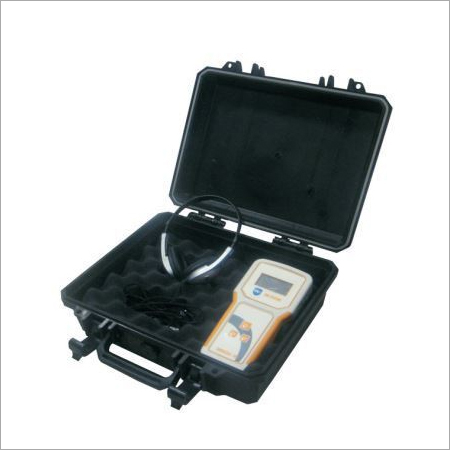

- Includes

- Transmitter, Receiver, Headphones, Carry Case, Batteries, Instruction Manual

- Sensitivity Adjustment

- Multi-level adjustable

- Detection Distance

- Up to 10 meters (directional)

- Indication Method

- Visual (LED) and Audible (headphones)

- Battery Life

- Approximately 30 hours continuous

- Working Frequency

- 36 kHz ± 2 kHz (Ultrasonic)

- Dimensions

- 180 mm x 40 mm x 35 mm (approx.)

- Carrying Case

- Included

- Calibration

- Factory calibrated

Ultrasonic Air Leak Detector UL-102 Trade Information

- Minimum Order Quantity

- 4 Pieces

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 3 Week

- Main Domestic Market

- All India

- Certifications

- CE

About Ultrasonic Air Leak Detector UL-102

- Pressure-less systems

- Freight containers

- Vehicles

- Ventilation technique systems and containers

- Apt for detecting leaks & mechanical malfunctioning

- Steam Trap Assessment

- Critical Valve Diagnostics

- Electrical Arcing & Corona Discharge occurs

- It is an instrument that is a part of Predictive Maintenance

- Range: 30 KHz

- Energy Savings

Specification

Probe | Airborne for external sound Touch probe for internal sound |

Sensitivity | -65 Db/ubar at 40 KHz |

Frequency Ranges | UL – 101 : 40KHz 1 |

Band Width | ± 2 KHz |

Displays | Alphanumeric Graphics LCD |

Headset | Dynamic 32 ohm |

Power Supply | 6 V Internal NiMH rechargeable battery |

Weight | 175 grams |

Dimension | 166 x 88 x 32 |

Case | High impact ABS Plastic |

Operating Temp. | 0-50 °C |

Storage Temp. | -20 °C to 60 °C |

Pinpoint Accuracy for Rapid Leak Detection

The UL-102 employs advanced ultrasonic technology to instantly identify leaks in compressed air and gas systems, even those too small for conventional methods to detect. Integrated LED bar indicators and headphones provide both visual and audible cues, allowing for accurate localization of leaks from distances up to 10 meters. This saves time and reduces maintenance costs.

Robust Design for Versatile Environments

With a durable ABS plastic shell and IP-certified components, the UL-102 operates effectively in both indoor and outdoor settings, within temperatures ranging from 0C to 40C and humidity up to 80% RH. It's lightweight, easy to handle, and comes packaged with a convenient carrying case for portability, making it an essential tool for on-site inspections.

User-Friendly Operation with Adjustable Sensitivity

Designed for ease of use, the UL-102 offers multi-level sensitivity adjustments to accommodate varying leak sizes and environments. The factory-calibrated system requires minimal setup and comes with a comprehensive instruction manual, empowering operators to quickly begin leak detection in any pressurized gas system.

FAQ's of Ultrasonic Air Leak Detector UL-102:

Q: How does the Ultrasonic Air Leak Detector UL-102 function to identify leaks?

A: The UL-102 detects ultrasonic sound waves generated by air or gas escaping from leaks. Its receiver captures these high-frequency signals, and results are displayed visually on an LED bar or audibly through headphones, enabling quick and precise localization.Q: What types of materials and systems can the UL-102 be used on?

A: This device is suitable for leak detection on metal, plastic, and rubber pipelines, valves, tanks, and fittings designed to handle pressurized air or gas, accommodating a wide variety of industrial and maintenance applications.Q: When should I use the UL-102 for the most reliable leak detection results?

A: For optimal accuracy, use the UL-102 during system operation when the pipes or tanks are pressurized with air or gas. Perform testing in environments within the recommended temperature (0C to 40C) and humidity (80% RH) ranges.Q: Where is the ideal placement for leak testing with the UL-102?

A: Position the receiver near suspected leak points such as joints, valves, or fittings. Thanks to its directional detection capability and up to 10-meter range, the UL-102 can also scan broader areas or hard-to-reach sections efficiently.Q: What is the process for adjusting sensitivity during leak detection?

A: The UL-102 features multi-level sensitivity adjustment to help filter background noise and enhance detection accuracy. Turn the sensitivity knob to increase or decrease as needed based on the size and environment of the leak.Q: How does using the UL-102 benefit maintenance routines and operational safety?

A: The UL-102 enables fast, non-destructive detection of even micro-leaks, significantly reducing downtime, preventing wastage of costly gases, and ensuring safer, more efficient system performance. Its real-time feedback aids prompt repairs, minimizing potential hazards.Q: What is included in the UL-102 package, and is calibration required?

A: Each UL-102 set comes with a transmitter, receiver, headphones, batteries, carrying case, and an instruction manual. The instrument is factory calibrated and ready for immediate use, requiring no further adjustment.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ultrasonic Leak Detector Category

Portable Ultrasonic Gas Leak Detector

Price Range 35000.00 - 98000.00 INR

Minimum Order Quantity : 2 Pieces

Temperature : 0 to +55 Celsius (oC)

Power Supply : 6 V DC rechargeable type

Operating Voltage : 230 V AC, 50 Hz Volt (V)

Ultrasonic Leak Detector

Price Range 30000.00 - 120000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Temperature : 50 Celsius (oC)

Material : ABS Plastic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese